When it comes to safety — and comfort — pressure comes into play in many ways. XSENSOR’s pressure sensor technology is geared towards helping to provide both, and our impact pressure sensors allow safety engineers to measure and respond to impact pressure at high resolutions and speeds. Our impact pressure sensor gives the automotive industry the ability to do everything from testing passive restraint systems with impact data from surfaces with the High-Speed (HS) Impact System.

Impact Pressure Sensor Overview

Impact Pressure Sensor Technology for Vehicles

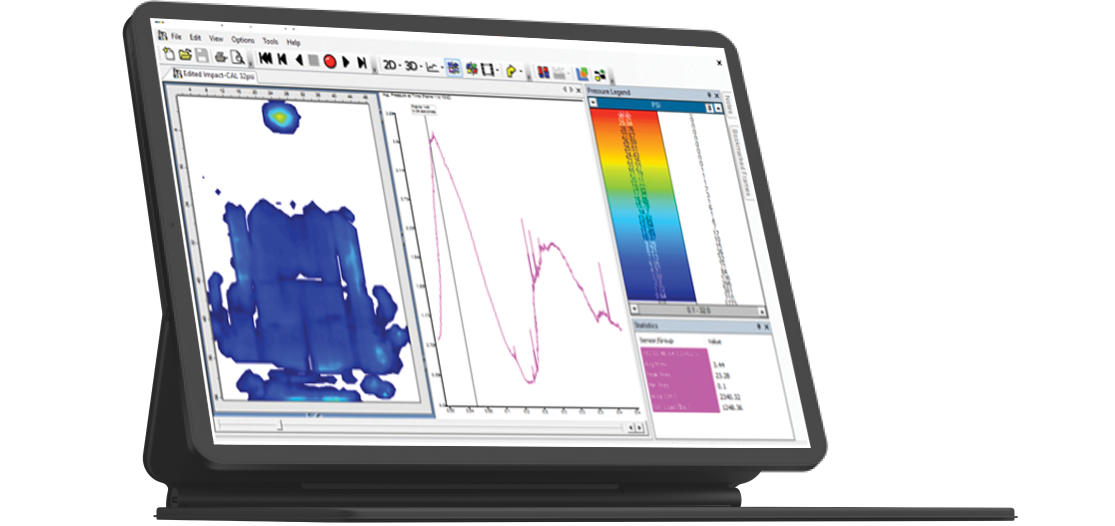

Using state-of-the-art technology, our HS Impact pressure sensor allows engineers to measure surface pressure distributions during and after sudden impacts. This ability helps engineers isolate issues, add effective solutions and have a measurement and data tool that stands the test of time.

Our impact pressure sensor software is built to provide live and post-process viewing and data analysis. The recordings from our impact pressure sensor synchronize with other data acquisition devices, which helps measure everything from product performance to pressure throughout impact.

Impact Pressure Sensor Specifications and Performance

XSENSOR’s pressure impact sensors are designed for accurate and consistent measurement, especially in periods of high-impact testing such as crash tests. Our pressure impact sensors provide consistent data over cycles, giving you higher equipment availability and reduced re-calibration frequency.

| HX impact pressure sensors contain thousands of sensing points that are sampled between 2,000 and 3,000 frames per second. | |

| Rugged data logger comes ready to mount to crash sleds and has programmable remote trigger options for repeated testing procedures. | |

| Impact pressure sensors are thin and conformable, with a fast response rate and are available in a range of sizes and pressure ranges. | |

| All data is consistent and repeatable on a cell-by-cell basis so you can capture exactly what happens during and after an impact. |